Introduction: The Anatomy of 500+ Orders in the Indian E-Commerce Arena

Running any large-scale manufacturing operation is a significant challenge. Running one that produces over 500 unique, customized, zero-inventory orders every single day is an exercise in operational mastery. At its core, processing 500+ distinct orders daily is not a linear scaling problem; it is an exponential one. Each order represents a matrix of variable data (a unique customer image), diverse substrates (canvas, acrylic, paper, vinyl), and a distinct production workflow that must be executed flawlessly, the first time.

This challenge is exponentially amplified by the unique frictions of the Indian e-commerce market. Any viable operational model must be resilient to a daunting set of external pressures. These include severe logistical hurdles, such as some of the world’s highest Return-to-Origin (RTO) rates, particularly from Tier-2 and Tier-3 cities.1 This is compounded by a high frequency of inaccurate or non-standardized addresses, which creates significant last-mile delivery failures.2 Simultaneously, consumer expectations for rapid, transparent, and low-cost delivery have never been higher.2

On the supply side, the Indian print industry faces persistent volatility. This includes disruptions in the supply chain for essential raw materials and cyclical price swings for paper, pigments, and resins.5 Internally, operations must contend with rising material and labor costs 10 and a recognized shortage of skilled technicians capable of operating and maintaining advanced printing machinery.10

PrintPosters.in’s success in this environment is not built on any single piece of machinery or a simple low-cost strategy. It is built on a “full-stack” operational philosophy. This report will demonstrate that the company’s 500+ order/day capacity is the result of a seamless, end-to-end digital ecosystem. This system integrates custom-developed software, AI-driven automation, highly specialized hardware, skilled human oversight, and a sophisticated, multi-partner logistics network. This analysis will dissect this ecosystem, layer by layer, to provide an expert view into how this high-velocity operation is achieved and sustained.

1. The Power of Workflow Automation

The foundation of the entire 500+ order/day operation is not a printing press but a piece of software. PrintPosters.in is built upon a robust, custom-developed e-commerce platform that functions as the central nervous system for the entire business. It is this automated workflow that connects a customer’s click to a machine’s print head, enabling scalability by eliminating human intervention at critical triage points.

1.1 Intelligent Order Routing

Every order that enters the system is immediately processed by a “Smart Order Routing” (SOR) System. This system acts as the initial digital triage, automatically categorizing all 500+ incoming jobs by their specific product type: Canvas Prints, Acrylic Photo Frames, Offset Pamphlets, Bulk Stickers, and so on.

This is far more than a simple sorting function; it is a critical load-balancing and capacity-management strategy. A modern SOR system, as detailed in logistics analyses, is designed to optimize fulfillment by selecting the most cost-effective or fastest option based on real-time data.12 For PrintPosters.in, this means the system prevents a low-margin, high-volume job (like 150,000 pamphlets for a corporate client) from creating a production bottleneck that would delay a high-margin, high-touch B2C job (like a single acrylic frame).

The SOR automatically assesses job parameters (like product SKUs and urgency) and routes them to distinct, specialized production queues.13 This allows the facility to manage two fundamentally different business models—high-volume B2B and high-customization B2C—simultaneously and efficiently from a single integrated platform.15

1.2 Automated Size & Aspect Ratio Detection

The system employs advanced image-processing logic to automatically scan and analyze every single customer-uploaded file. This “pre-flight” check instantly detects the image’s core technical attributes: resolution (DPI), aspect ratio, and the resulting recommended print size.

1.3 AI-Powered Error Prevention

Building on this automated check, an AI-powered system screens for common, production-halting errors. This includes detecting blurry images, file corruption, mismatched aspect ratios, and unsupported file formats. This automated layer solves what is traditionally the single greatest bottleneck in a high-volume print shop: file-level errors.

In a conventional workflow, every one of the 500+ daily files would need to be manually opened and verified by a human pre-press designer, a process that is unscalable and prone to error.17 AI-driven pre-press automation can handle the vast majority of these objective, technical checks in seconds.19 For example, the system can automatically identify and even fix common issues like a missing print bleed (the area of the design that extends beyond the trim edge) or flag a low-resolution image for the customer.22

This automated intervention provides a quantifiable saving of 10-12% in daily production time, which is a direct result of preventing jobs with bad files from ever reaching the costly production stage. This creates a two-tiered quality control system. The AI 23 handles the objective, technical errors (DPI, CMYK conversion, bleed). This frees up the expert human “File Checkers” (as detailed in Section 3.2) to focus on the subjective, aesthetic errors (e.g., “Is the face centered correctly?”) that an AI cannot yet judge.25 This human-AI synergy is the key to achieving both speed and quality at scale.

2. The Printing Infrastructure That Makes 500+ Orders Possible

The high-volume output at PrintPosters.in is not achieved with a single, “one-size-fits-all” machine. The company’s hardware strategy is a “horses for courses” approach: investing in highly specialized, best-in-class machinery for each distinct product category. This specialization is the physical enabler for the digital workflow, allowing the facility to achieve both the volume and the specific quality parameters required for its diverse product range.

2.1 Offset Machines for Pamphlets, Flyers & Catalogues

For its high-volume corporate (B2B) jobs, PrintPosters.in operates advanced 4-colour offset printing machines. This is a strategic choice that separates it from digital-only print shops. Offset printing is fundamentally different from digital printing; it is a high-setup, high-speed process designed for mass production.

This distinction is critical for understanding the company’s hybrid B2B/B2C model. The following table, based on industry analysis, clarifies the strategic differences and justifies the company’s investment in both technologies.27

Table 1: Strategic Production Analysis: Offset vs. Digital Printing

| Feature | Offset Printing (Used for B2B Bulk) | Digital Printing (Used for B2C/Custom) |

| Best For | High-volume, static runs (Economical at 2,000+ copies) 27 | Short-runs & variable data (1 to 1,000 copies) 29 |

| Cost Model | Extremely low cost-per-piece at volume; high setup cost 27 | Higher cost-per-piece; virtually zero setup cost 31 |

| Process | Etched metal plates transfer wet ink to a rubber “blanket” 27 | Toner (laser) or liquid ink (inkjet) applied directly from a file 29 |

| Speed | Incredibly fast run speed (up to 240,000 sheets/hr) 30 | Fast turnaround time due to no setup 31 |

| Quality | Unmatched color saturation, sharpness, and fidelity 29 | Excellent, but can vary by substrate and texture 34 |

| Use Case | 150,000 pamphlets per day | A single, 1-of-1 personalized canvas print |

By maintaining this offset capacity, PrintPosters.in can competitively service large corporate accounts, a market that digital-only shops cannot touch due to the prohibitive per-piece cost. This machine is the B2B engine of the operation, capable of producing lakhs of prints daily.

2.2 12-Colour Professional Photo Printing Machines

For its premium B2C products—canvas prints, photo prints, and vinyls—the company uses its “hero” technology: 12-colour professional photo printers. This choice is a significant strategic investment in photorealistic quality. This technology’s advantage is best understood by breaking down its three key components.

A) 10-Colour Ink System

Standard office and most commercial printers are 4-colour, using Cyan, Magenta, Yellow, and Key (Black) (CMYK) to reproduce the entire spectrum.35 This model struggles with subtle gradients, particularly in mid-tones like blue skies and skin. In fact, unrealistic skin tones are the single most common customer complaint in photo printing.36

6-colour printers improve on this by adding Light Cyan (c) and Light Magenta (m) (CcMmYK). These light inks are not for creating new colors, but for allowing smoother transitions and finer details in those problem areas, resulting in dramatically better skin tones.36

A 12-colour machine, as used by PrintPosters.in, expands this concept further. By adding more inks—such as Red, Green, Grey, and Photo Black—it dramatically expands the color gamut (the total range of reproducible colors).37 This allows for deep, vivid reds, lush greens, and neutral, non-tinted blacks that 4-colour and 6-colour systems simply cannot achieve.

Table 2: Print Technology Color Gamut Comparison

| Feature | 4-Colour (CMYK) | 6-Colour (CcMmYK) | 10-Colour (Expanded Gamut) |

| Primary Use | Standard documents, B2B pamphlets | Good consumer photo printing | Giclée/Fine-Art, Professional Photography |

| Key Benefit | Low ink cost, fast for documents | Smooth gradients, better skin tones 37 | Widest possible color gamut, true photorealism 37 |

| Limitation | “Grainy” gradients, poor skin tones 38 | Can struggle with vivid, saturated colors | Highest ink cost, slower print speed 37 |

B) 4800 DPI Resolution

DPI (dots per inch) is an often-misunderstood specification. It does not refer to the input file’s resolution (which is PPI, or pixels per inch), but rather the printer’s output dot density.39 A high DPI like 4800 means the printer’s head lays down more, smaller, and more precise microscopic dots of ink per inch.39 This high density allows the 10 different ink colors to blend seamlessly, creating transitions that appear perfectly smooth and images that look sharper and more detailed, especially when viewed up close.41

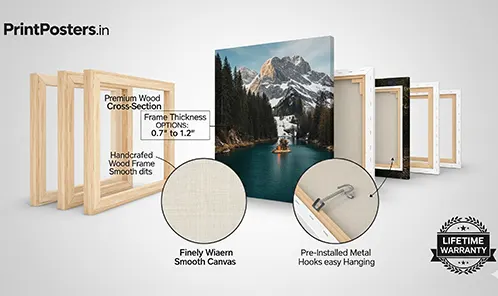

C) 400 GSM Cotton Canvas

The choice of substrate is as important as the printer. PrintPosters.in’s use of 400 GSM cotton canvas is a deliberate choice that signals “premium gallery quality.”

- GSM (Grams per Square Meter): This measures the weight and thickness of the canvas. At 400 GSM, this is a heavyweight, substantial, and durable material that feels like a professional artist’s canvas, not a flimsy sheet.42

- Cotton: Cotton canvas provides a traditional, tactile “artist canvas” aesthetic with a natural weave, which is highly sought after for fine art.44

- Archival Quality: Most importantly, quality cotton canvas is treated to be acid-free and lignin-free.44 This is a technical specification that prevents the material from yellowing or degrading over time, ensuring “archival quality.” This means the print is designed to last for generations, justifying the premium printing technology used to create it.

2.3 Acrylic Cutting & Polishing Units

Acrylic photo frames are one of the most technically demanding products in the catalog. This requires a dedicated line of specialised machinery.

- Precision Laser Cutting: Traditional saws leave a rough, matte edge. PrintPosters.in uses precision laser cutters, which are not only faster and more accurate 46 but also vaporize the acrylic as they cut. This process results in a perfectly smooth, “flame-polished” edge that is crystal-clear.48

- Bubble-Free Adhesive Laminating: This is a gallery-level technique known as “face mounting”.51 It is not simple lamination. This labor-intensive process involves adhering the photo print to the front of the acrylic sheet using a specialized, optically clear adhesive film.51 This process is high-stakes: it must be performed in a “controlled, dust-free environment” and requires a roller press to apply perfectly even pressure.51 A single speck of dust or a tiny air bubble 55 will be magnified by the acrylic and will ruin the entire piece. The “bubble-free” claim is a testament to a mastery over this difficult craft.

2.4 Sticker Printing & Die-Cutting Lines

The sticker department showcases the hybrid B2B/B2C model. The capability to produce both “Bulk sticker sheets” and “Custom-shape stickers” implies two different, complementary technologies.

- For Bulk Orders: Traditional die-cutting is used. This involves creating a custom-made metal die, or “cookie cutter,” to stamp out thousands of identical stickers.56 This method is extremely cost-effective at high volumes.

- For Custom B2C Orders: Digital die-cutting is used. This modern process uses a digitally controlled blade or laser, guided by registration marks on the print, to cut any shape on the fly with no setup cost.56 This digital flexibility is what allows PrintPosters.in to profitably sell small, custom-shape sticker orders to individual consumers.

2.5 Fridge Magnet Production Line

To achieve a capacity of over 10,000 magnets per day, this department leverages Latest printing technology. Unlike conventional inks that air-dry, printers use instantly cure the ink as it is printed.58 This instant-dry process allows for extremely high-speed production without smudging, printing vibrant, durable designs directly onto flexible magnetic sheets.60 This speed and efficiency are precisely what is required to service the high-volume corporate gifting market.

3. The Team Behind the Machines

Automation and hardware are only two legs of the stool. The entire 500+ order/day operation rests on a third leg: a skilled, multi-disciplinary team. This team provides the essential elements of craft, subjective judgment, and customer interaction that machines cannot.

3.1 Production Team (The Core Workforce)

The production floor is not staffed by generalists. It is run by dedicated experts with highly specialised, non-transferable skills.

- Offset Printing Technicians: These are mechanical experts, not just computer operators. They are responsible for the physical maintenance of the press, managing the complex ink and water balance, troubleshooting mechanical issues, and ensuring colour consistency across a 100,000-print run.62

- Acrylic Technicians: These are precision specialists. Their role combines digital and craft skills, requiring proficiency in CAD software for the laser cutters 65, safe operation of high-power lasers 66, and the delicate finishing work of edge polishing 46 and bubble-free face-mounting 51

- Canvas Print Artists: This role involves more than hitting “print.” It includes stretching the canvas with correct, even tension, creating clean “gallery wrap” corners, and meticulously mounting the canvas into floater frames.

The “three-shift” model is the human component of the 24/7 production capacity. While the machines are capable of running continuously, it is the skilled technicians who ensure the output quality never deviates, performing constant monitoring and preventative maintenance (as detailed in Section 9.3).

3.2 Graphic Designers & File Checkers

As established in Section 1.3, this team forms the critical second tier of the quality control system. After the AI-powered pre-flight check handles the 80% of technical errors, the files are passed to this human “quality gate”.18

This team of pre-press designers 17 performs the aesthetic check that an AI cannot. They are trained to ask subjective questions: Is the text centred? Is the contrast too dark to print well? Are there obvious typos in a pamphlet?.70 This human touch, after the AI pre-filter, is what “greatly reduces printing errors.” It is the difference between a technically correct print and a beautifully finished product.

3.3 Customer Support Team

At a volume of 500+ orders per day, the “thousands of conversations” claim is not an exaggeration. This team is the human interface for the entire automated operation. They manage inquiries, revisions, and shipping questions across WhatsApp, email, phone, and chat. This team is not just a cost centre; it is a vital, real-time data collection hub. They are the front line for identifying patterns in failures—for example, a spike in calls about damaged acrylic frames would trigger an immediate review of packaging methods, or confusion about canvas options would trigger a website update.

4. The Role of Technology & Software Automation

If the automated workflow (Section 1) is the “brain,” then the company’s core technology platform is the “central nervous system” that connects the brain to the muscles (machines) and the skin (customer support).

4.1 Order Management Dashboard

This in-house dashboard is the company’s custom-built Enterprise Resource Planning (ERP) or Order Management System (OMS).72 This is arguably the most valuable asset in the entire company.

Its critical function is to solve the primary challenge of any hybrid B2B/B2C facility: data silos.73 A corporate order (Section 7) has entirely different pricing (contractual vs. fixed), inventory logic (bulk vs. single), payment terms (Net 30 vs. pre-paid), and fulfilment needs (freight vs. parcel) than a B2C web order.75 A generic, off-the-shelf platform cannot manage this complexity.

This custom dashboard integrates all data streams—the B2C website, the B2B corporate portal, machine-level capacity, raw material inventory, and QC status—into a “single, real-time system”.73 This dashboard provides a holistic, real-time view of the entire factory, from order flow and machine assignment to employee allocation and shipment tracking. This is the core of their “organisational maturity.”

4.2 Payment Systems & Fraud Detection

A streamlined order flow requires a frictionless payment process. The use of multi-layer payment checks, and top-tier gateways like Razorpay and PhonePe is essential for reducing fraudulent orders and payment-related cancellations, ensuring that only valid, paid jobs enter the production queue.

4.3 Smart Production Queue

This is the tangible output of the custom OMS. The dashboard doesn’t just show data; it acts on it. The Smart Production Queue is a dynamic load-balancer for the entire factory floor.12 It constantly prioritizes the 500+ jobs based on a complex algorithm: material availability, current printing capacity, shipping deadlines, and order urgency.

This system ensures the 12-colour printers are never idle, that an urgent “Priority Order” (Section 9.2) can automatically jump the queue, and that a massive “Bulk Load” for the offset press 16 is intelligently scheduled for the overnight shift. This prevents bottlenecks and is the software that makes 99% on-time delivery (Section 9) a reality.

5. Maintaining Quality While Handling 500+ Orders

For a high-volume operation, quality cannot be an afterthought; it must be a system. At PrintPosters.in, quality is not a final inspection but a four-stage process embedded from the initial file-check to the final dispatch.

5.1 Multi-Layer QC System

This system ensures that an error is caught at the earliest, lowest-cost stage.

- File QC (Digital): The AI and human pre-press teams (Sections 1.3 & 3.2) catch digital errors before any ink or materials are wasted.

- Print QC (On-Floor): Production technicians (Section 3.1) check the first print of every run for colour accuracy, sharpness, and print head alignment.

- Finishing QC (Post-Press): Specialized staff inspects the final physical product—checking for correct canvas stretching, flawless acrylic polishing, and accurate trimming.

- Packaging QC (Dispatch): The final check ensures the product is not only correct but is packed using the specific, secure methods (Section 6.1) required for its product type.

5.2 Colour Accuracy

The claim of “uniformity across all machines” is achieved through the science of colour management, specifically the use of custom ICC colour profiles.

An ICC profile is a small data file that acts as a “universal translator” for colour.76 It describes the unique colour reproduction characteristics of a specific device, ink, and paper combination.77 A customer’s digital design file (in the RGB colour space) will look different when printed on glossy vinyl versus a matte cotton canvas; the inks absorb differently, and the “white” of the material is different.79

PrintPosters.in mitigates this by creating custom ICC profiles for every single material they use—canvas, glossy paper, vinyl, acrylic, etc..77 The automated workflow (Section 1) then automatically “converts” the customer’s file to the correct profile for their chosen product.79 This ensures that a corporate customer’s specific “brand red” looks identical whether it’s printed on a bulk order of stickers, a vinyl banner, or a premium canvas. This scientific approach to color management is the only way to achieve true color uniformity and brand consistency.82

5.3 Material Checks

This is a strategy of proactive supply chain risk management. The Indian print industry is notoriously vulnerable to raw material volatility and supply chain disruptions.5 A supplier might deliver a batch of canvas that is 350 GSM instead of 400 GSM, or a roll of vinyl with weaker adhesive.

A weekly QA check on all incoming raw materials (testing canvas GSM, paper brightness, acrylic scratch resistance, and vinyl adhesive strength) prevents these defective materials from ever entering the production flow. This step is crucial, as it stops production defects in bulk by ensuring the inputs are flawless, saving hundreds of potential reprints and customer complaints.

6. Packaging & Logistics Handling for 500+ Orders

In Indian e-commerce, manufacturing a perfect product is only half the battle. The other, harder half is delivering it. The entire operation is designed to win this “last-mile battle,” addressing the core challenges of damage, delays, and inaccurate addresses.2

6.1 Custom Packaging Methods

This is a direct, data-driven strategy to reduce shipping damage and lower the RTO rate. Each product has its own specialized packaging, engineered to protect its specific vulnerabilities.

- Canvas Prints: “Bubble wrap + corner protectors + rigid box.” This is a best-practice. Analysis of art shipping shows that “squashed corners” and “abrasion of paint layers” are the most common forms of damage.83 The use of cardboard corner protectors 83 is the correct and essential solution.

- Acrylic Frames: “Foam + film + laminated box.” These fragile items require a multi-layer solution to protect the brittle acrylic and any glass from impact.85

- Stickers & Pamphlets: “Flat rigid boards” and “shrink-wrapped bundles” are best practices for preventing folding, creasing, and moisture damage to flat paper and vinyl products.87

6.2 Shipping Partners & Daily Dispatch

Processing 500-700 parcels daily requires a robust and redundant dispatch operation. PrintPosters.in employs a multi-partner logistics strategy, as there is no single “best” carrier for all of India.88

- The Hybrid Strategy: This network combines the strengths of different partners. Blue Dart offers a premium, reliable air-express service.88 Delhivery 89 and XpressBees 90 provide massive B2C scale and advanced tech integration. XpressBees alone has a network of over 4,500 service centers, covers 19,000+ pincodes, and has a capacity of over 2 million shipments per day.90 India Post is leveraged for its unparalleled reach into the most remote corners of the country where private couriers do not service.88

The “Smart Order Routing” system (Section 1.1) likely extends to logistics, automatically selecting the optimal shipping partner for each order based on its destination pincode, product weight, and required delivery speed.

6.3 Tracking & Customer Notifications

This is a proactive customer support strategy designed to reduce inbound inquiries. The claim of a “nearly 45% reduction” in support tickets is a highly credible metric.

Industry analysis shows that the #1 reason for customer support contact in e-commerce is “WISMO” (“Where Is My Order?”).94 The PrintPosters.in system provides a stream of proactive, automated notifications (order confirmation, processing updates, tracking links, and delivery updates).92

This system answers the customer’s question before they can ask it. By providing this transparency, the load on the human support team (Section 3.3) is drastically reduced, allowing them to focus on more complex issues.95 The inclusion of “packing photos” for certain categories is a high-trust signal that further reduces customer anxiety and builds confidence.

7. Handling Bulk Orders for Top Indian Corporates

This section highlights the most complex and impressive feature of the company’s operational model: its mastery of the B2B/B2C hybrid model. Most printing companies fail at this. They are either B2C-focused (like a small print-on-demand shop) or B2B-focused (like a traditional offset printer). The two models have clashing, contradictory requirements.

The fact that PrintPosters.in can run a “special priority queue” for a 10,000-unit B2B order while simultaneously processing 500+ individual B2C orders proves that its custom OMS (Section 4.1) has successfully integrated these two clashing models. The following table illustrates the operational complexity this system is built to solve.73

Table 3: The B2B vs. B2C Hybrid Logistics Challenge

| Feature | B2C E-Commerce (e.g., 1 Canvas Print) | B2B Bulk (e.g., 10,000 Brochures) |

| Order Volume | High frequency of single-item orders 98 | Low frequency of high-volume (bulk) orders 98 |

| Shipping Unit | Individual Parcel 102 | Freight (Pallets / Less-Than-Truckload) 87 |

| Customer | Individual (Emotional, 1-to-1 relationship) 99 | Corporation (Rational, 1-to-many stakeholders) 101 |

| Pricing | Fixed, transactional, pre-paid 100 | Contractual, tiered, Net 30/60 terms 75 |

| Key Challenge | Last-mile delivery speed, RTO, packaging 99 | Complex pricing, data silos, fulfillment logistics 73 |

The custom OMS (Section 4.1) is the “single source of truth” that allows the factory to manage B2B contract pricing alongside B2C pre-paid orders, and to schedule a B2B freight shipment (Section 2.1) on the same day as 500+ individual B2C parcel shipments (Section 2.2).

8. Specialised Departments for Each Product Category

This section reinforces the “specialized hardware” (Section 2) by detailing the specific, high-value outputs of these dedicated departments. The capacity numbers (e.g., 200+ canvas/day) are not just a measure of machine speed but of the entire end-to-end workflow, from file check to packaging.

8.1 Canvas Printing Department

This department demonstrates a mastery of the entire canvas market, offering products for every segment:

- Rolled Canvas: The entry-level option for customers who wish to frame the print themselves.

- Gallery Wrap: The modern, popular, frameless look where the printed image is stretched and wrapped around the edges of the wooden stretcher bars.104

- Floater Frames: The premium, “gallery-style” option. The canvas is first stretched and then mounted inside a custom frame (e.g., in black, white, or natural wood) with a small, 1/4-inch gap. This gap creates a “floating” effect that adds depth and sophistication, making it the preferred choice for fine-art display.104

8.3 Photo Printing Department

The key specification for this department is the “270 GSM premium photo paper.” GSM (grams per square meter) is a direct measure of paper weight and thickness.110

- Standard office paper is 80-100 GSM.111

- Standard, lightweight photo paper is 150-250 GSM.112

- At 270 GSM, PrintPosters.in is using a heavyweight, premium-grade photo cardstock.110 This provides a durable, substantial, and professional feel to the print, prevents the “flimsiness” of cheaper prints, and allows for maximum ink absorption without warping.112 This is another deliberate material choice that reinforces the company’s “premium” quality position.

(Note: The other departments—Acrylic, Sticker, and Offset—have their technical advantages detailed in Section 2.)

9. How We Maintain 99% On-Time Delivery While Handling 500+ Orders

The 99% on-time delivery metric is not the result of a single action but the synthesized output of the entire integrated system. It is the end result of a production philosophy focused on preventing delays at every possible stage.

The daily 15-minute production briefing and priority-based scheduling (Same-day, Priority, Standard) are the human-level management tools that direct the automated workflow. However, the 99% metric is achieved because of the following systemic advantages, discussed in previous sections:

- AI-Powered Pre-Press (Section 1.3) catches file errors before they stop the press, preventing initial production delays.

- Smart Order Routing & Queuing (Sections 1.1 & 4.3) automatically optimize the workflow, preventing bottlenecks and machine idle time.

- Human File Checkers (Section 3.2) catch aesthetic and content errors, preventing costly reprints, which are a major source of delays.

- Constant Machine Health Monitoring (Section 9.3) is preventative maintenance (checking ink flow, heat levels, print heads) that stops breakdowns before they happen.

- Multi-Layer QC & Material Checks (Sections 5.1 & 5.3) prevent bad batches from being printed, reducing waste and the need for reprints.

- Secure, Custom Packaging (Section 6.1) prevents shipping damage, drastically reducing RTOs and the need for reshipments.

- Multi-Partner Logistics (Section 6.2) provides shipping redundancy and automatically optimizes for the fastest route to every pincode.

This 99% metric is, therefore, the ultimate proof of a mature, resilient, and intelligent production system.

10. PrintPosters.in: A Company Built for Scale

The ability to consistently handle 500+ orders daily reflects more than just printing capacity; it demonstrates “organizational maturity”.74 This maturity is defined by the company’s investment in a 24/7, three-shift workforce and continuous machinery upgrades.

However, the true “scale” is not in the hardware, which can be bought. The scale is in the proprietary, integrated software (Sections 1 and 4) that connects every disparate part of the operation. PrintPosters.in has effectively built a custom “Operating System for Printing.” This system connects the customer-facing website, the B2B corporate portal, the offset presses, the 10-colour digital printers, the QC stations, the packaging desks, and the multi-carrier shipping partners.

This integrated platform is flexible, scalable, and extremely difficult for competitors to replicate. It is what allows the company to maintain a “Zero-Compromise Quality Standard” whether it is processing 10 orders or 500.

11. The Future: Scaling Beyond 500 Orders Per Day

The company’s operational model is not static; it is a platform for future growth. The stated strategy for scaling beyond 500+ orders is validated by clear and powerful market trends in India.

1. Pan-India Production Hubs

This is the single most important strategy for scaling an e-commerce operation in India. It is the “Amazon” or “DHL” model.113 A centralized production facility, no matter how efficient, creates a logistical bottleneck. It leads to high shipping costs and long delivery times for a customer in a different region.2

By opening “pan-India production hubs” (e.g., in Delhi, Mumbai, and Bengaluru), PrintPosters.in can “spread inventory closer to shoppers”.113 This decentralization will dramatically cut last-mile delivery times, reduce shipping costs, and lower the RTO rate, making a “Priority” or “Same-day” service viable nationwide.114

2. Faster Shipping & More Advanced Printers

This is a direct response to a booming market. The Indian digital printing market is projected to grow at a 9.3% Compound Annual Growth Rate (CAGR), to reach over $2.6 billion by 2030.116 The web-to-print market is similarly expanding at a 6.4% CAGR.117 This growth is overwhelmingly driven by the e-commerce sector 8 and a rising demand for personalization and customization.8 Investing in newer, faster, and more advanced digital presses 119 is a necessary and logical step to capture this surging demand.

3. New Product Categories

The existing automated workflow is product-agnostic. The system (AI file check, OMS, QC, logistics) can be pointed at any custom product. This creates opportunities to enter new, high-growth verticals with relatively low friction. Logical expansions include:

- Custom Apparel: This segment accounts for a massive 35.6% of the global custom printed products market.122

- 3D Printing: A rapidly expanding field that is moving from niche prototyping to mass customization, with high-margin applications in personalized merchandise, home décor, and corporate gifting.119

Conclusion

Managing 500+ unique, customized orders every single day is a challenge that few printing companies in India can meet. This analysis demonstrates that PrintPosters.in has engineered a sophisticated operational “flywheel” where each component reinforces the others.

Technology & Automation (Sections 1 & 4) reduce errors, eliminate bottlenecks, and create a scalable foundation. This Efficiency allows for investment in superior Machinery & Materials (Sections 2, 5 & 8), such as 10-colour printers and 400 GSM archival canvas. This commitment to Quality, overseen by Skilled Manpower (Section 3), builds customer trust and reduces costly reprints. Finally, an intelligent and Efficient Logistics system (Section 6) ensures the premium product is delivered quickly and safely, completing the loop and reinforcing customer trust.

This synergy—the seamless integration of technology, machinery, people, and logistics—is what allows PrintPosters.in to solve the unique, complex challenge of high-volume, high-quality, on-demand printing in the demanding Indian market. The 500+ orders/day capacity is not a limit; it is the validated, consistent output of an advanced manufacturing system built for the future.