The process of making boxes for product packaging can be a complicated one, but there are some fundamental steps that you can follow to simplify the process. The following is a concise guide to making and printing boxes:

Find out what dimensions the box should have in order to fit your product. The dimensions of your product should be measured, and then a few extra inches should be added to each side to allow for padding and protection.

Make a decision about the kind of material that will make up your box. There is a wide variety of choices available, including plastic, cardboard, and corrugated cardboard. You can use either scissors or a box cutter to cut out the shape of your box. Be sure to leave flaps at the edges of the box so that they can be folded up and used to secure the box after it has been closed.

After the flaps of the box have been folded up and glued or taped into place, the box can be used. If you want your product to remain undamaged through the shipping process or while it is being stored, check that the box is strong and has a lock on it.

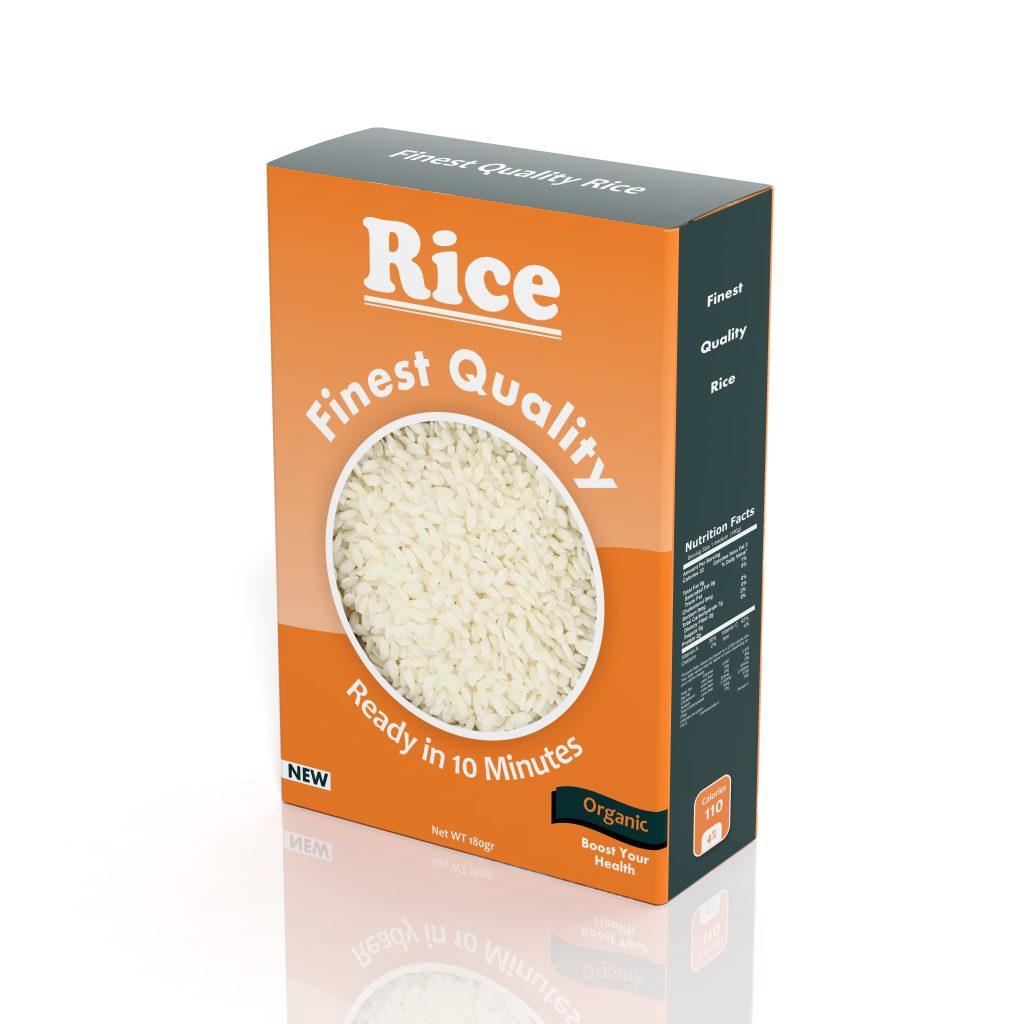

You should print the label or design for your box. You can accomplish this goal by using either a printer at home or the services of a commercial printing company. Make sure that the design or label you choose is the appropriate size for your box and that it includes all of the necessary information, such as the name of your company, its logo, and the specifics of the product. You can stick the printed picture or label to the top of your box with tape or glue. Check that it is attached firmly and that it looks as though it was done professionally.

Put your product inside the box and make sure it’s completely enclosed. Make certain that it has sufficient padding and protection so that it can be delivered to its location without being damaged. Pick the appropriate material for your box. The material that you pick for your box will depend on the kind of product that you are packaging, the weight of the product, and the shipping method that you will be using. As an illustration, if you are shipping items that are easily broken, you might want to select a corrugated cardboard box for the added protection it provides.

Take into consideration the printing process. Printing on cardboard containers can be done in a variety of ways, including digital, offset, and flexographic printing. Because each approach has a unique set of benefits and drawbacks, you need to select the strategy that is most conducive to the success of your endeavour.

Create a high-quality label or design. The label or design on your box is often the first thing a customer sees about your product, so it’s important to make sure it looks both professional and appealing. You might want to think about working with a graphic designer to come up with a unique look for your box.

Make sure you pick the right printing company. If you do decide to work with a printing company, it is important to pick one that has a solid reputation, years of experience, and the ability to deliver both high-quality printing and excellent service to their clients.

Test your boxes before you begin printing a large quantity of them. Before you begin printing a large number of boxes, it is a good idea to test your design and box to ensure that they are the appropriate size, shape, and durability for your product.

Box making and printing for product packaging can be a challenging process overall, but if you follow these basic steps, you will be able to create a package that looks professional, protects your product, and contributes to the success of your business. When it comes to a product’s success on the market, the packaging that it comes in can play a significant role. A well-designed package can catch the eye of potential buyers, give them important information about the product, and set it apart from other products in the same category.

The following are some of the ways that the design of product packaging can help sell products:

Get people’s attention: In a crowded marketplace, a product that stands out thanks to its attractive packaging has a better chance of attracting the interest of potential customers. Making a product stand out on the shelf can be accomplished through the use of contrasting colours, interesting shapes, and distinctive packaging materials.

Tell people about the product: the design of the packaging can also tell people about the features, benefits, and ingredients that are included in the product. By reading labels that are clear and to the point, customers can make better decisions about whether or not the product is right for them.

Make an emotional connection: If a package is well designed, it can also make a connection with the customer by making them feel something. This is another way to make a connection. A product with a design that is nostalgic or sentimental, for instance, may appeal to customers who are looking for a sense of comfort or familiarity in their purchases.

Differentiate yourself from your rivals: A well-designed piece of packaging can help a product stand out from the crowd of similar items on the shelf. In a market where there is a lot of competition, having a design that is both distinctive and easily recognizable can be extremely helpful in building brand recognition and loyalty.

Send a message to the target audience regarding the brand’s values: The way in which the product is packaged can also communicate something about the personality and ideals of the brand. For instance, a company that cares about the environment might use eco-friendly packaging, whereas a luxury brand might use high-quality materials and an elegant design. Both of these strategies are used to differentiate themselves from competitors.

The design of the packaging has the potential to influence customers’ decisions regarding their purchases. Ipsos conducted a study in which they found that more than one-third of customers base their purchasing decisions on the packaging of the product. Customers can be persuaded to make a purchase if the product’s value is communicated via a package that has been thoughtfully designed.

The way a product is packaged can increase both its real value and how much people think it is worth. Customers might get the impression that the product is worth more than it actually does if it comes in an attractive and high-quality package. This may be the most important thing when it comes to high-end products, whose packaging may have a big impact on whether or not customers are willing to pay more.

Make the user’s experience better by making the product’s packaging more appealing. This can also help the user form a better opinion of the product as a whole.

For example, giving customers a product with easy-to-open packaging or that can be used for more than one thing can make them happy and make them more likely to buy the product again.

The design of the product’s packaging can also be changed to make it more appealing to the type of people who will be buying it. For example, a product aimed at children might have bright colours and fun designs, while a product aimed at older people might have bigger text and more straightforward packaging.

Be adaptable to changing trends. The design of packaging can be changed to match the changing tastes and trends of consumers. As an illustration, materials for packaging that are better for the environment are gaining popularity as people become more concerned about the environment.

When taken as a whole, the manner in which a product is packaged can have a significant impact on how successful it is on the market. A package that has been carefully designed can help sell products and build brand recognition and customer loyalty by getting people’s attention, giving them information, creating an emotional connection, standing out from competitors, and sharing the brand’s values.