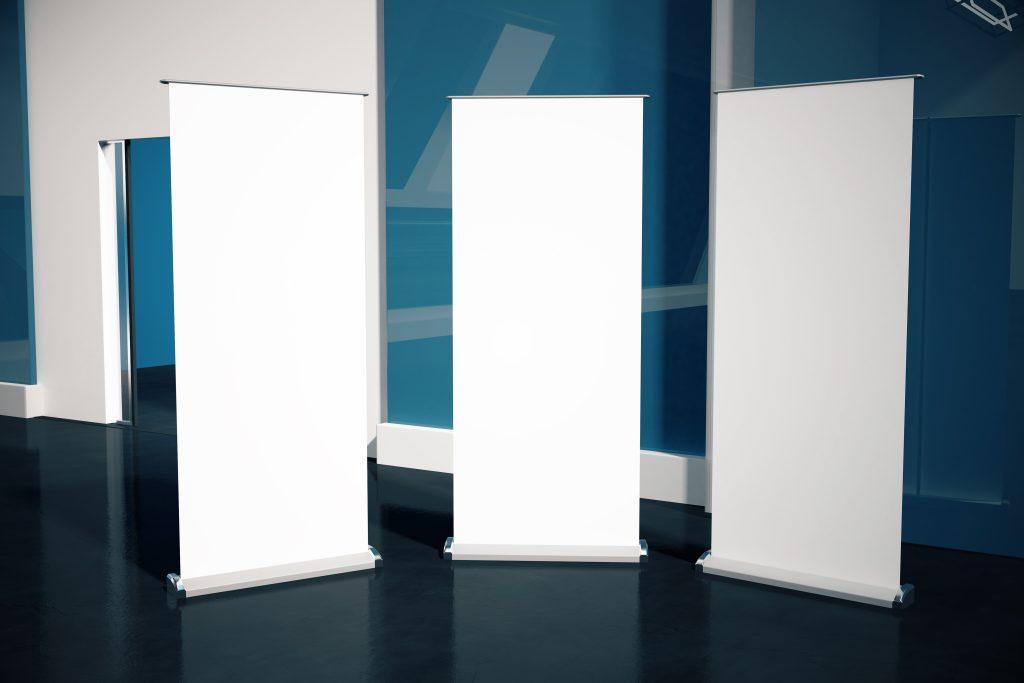

Roll-up standees are a common and popular type of standee that are frequently utilised for a variety of purposes, including retail displays, trade shows, and events. Due to the fact that they are designed to be portable and simple to assemble, they are an excellent option for companies that are looking for an advertising solution that is both flexible and versatile. Printing on roll-up standees requires a few steps, including the design, printing, and assembly of the finished product.

The design phase is the first step in the process of printing roll-up standees. A graphic designer is someone who creates images and other graphics by employing computer programmes like Adobe Photoshop and Illustrator. After that, a high-resolution digital file is created from this design, which is ultimately put to use in the printing process. It is essential to make certain that the layout is legible and understandable even when viewed from a distance.

After that, using large-format digital printing equipment, the image is printed onto a vinyl material of the highest possible quality. The fact that vinyl is a material that is both long-lasting and resistant to wear and tear makes it an excellent choice for a portable standee. The printing procedure guarantees that the image will be of a high quality and vivid colour.

Following the completion of the printing process, the picture is then affixed to a mechanism that rolls up. Because of this mechanism, the standee can be transported and assembled with relative ease. The roll-up mechanism is typically made of aluminium and includes a retractable pole that can be extended to hold the standee in place. Additionally, the roll-up mechanism can be folded flat for storage.

After the image has been firmly attached to the roll-up mechanism, the standee is prepared for use and can then be used. It can be carried around in a convenient carrying case and assembled in a matter of minutes. Roll-up standees are designed to be lightweight and easy to assemble, making them an ideal choice for businesses that need to promote their products or services at a variety of events and locations across the country.

Printing roll-up standees is a common practice that yields positive results when used to promote goods and services. In order to complete the process, you will need to create an image of high quality, print it onto a material made of durable vinyl, and then mount it onto a roll-up mechanism. The finished product is a lightweight and adaptable standee that can be utilised in a number of different environments.

When it comes to printing on roll-up standees, there are a few different considerations that should be made. The first factor to consider is the dimensions of the standee. There is a range of sizes available for roll-up standees; however, the most common dimensions are 80 cm by 200 cm, 85 cm by 200 cm, and 100 cm by 200 cm. It is essential to pick a standee that is the appropriate size for the event or location where it will be displayed, and this choice must be made with care.

The design of the standee is also something that should be considered. The picture or graphic needs to be interesting to look at while also effectively communicating the intended meaning. It ought to also be of high quality and simple to read even when one is some distance away. If you want more people to recognise your brand, it is smart to incorporate the company’s logo or other identifying features into the design.

Another important consideration is the kind of material that was used for the standee’s printing. As a result of its durability and adaptability, vinyl is the material that is utilised the most frequently in the production of roll-up standees. In addition to that, it is not susceptible to fading and is simple to clean. However, depending on the particular requirements of the project, roll-up standees can also be printed on other materials such as paper or fabric in addition to traditional cardboard.

One must take into account the process of assembling the standee. Roll-up standees are intended to be simple to erect and dismantle once they have served their purpose. The mechanism for rolling up the standee should be robust, and the pole should be attached to the standee in a reliable manner. In addition, a carrying case ought to be offered for convenience during transport.

Roll-up standee printing is an efficient marketing tool that can be used to promote products and services at events, trade shows, and retail displays. This type of printing can be done on a variety of materials, including vinyl, fabric, and foam core. It requires the creation of an image of high quality, printing it onto a material that is long-lasting, and mounting it onto a mechanism that rolls up. Roll-up standees have the potential to be an efficient and cost-effective method of reaching potential customers and increasing brand recognition when they are designed, sized, made of the appropriate material, and assembled correctly.

Printing on roll-up standees requires a multi-step process during production in order to achieve the desired results. The following is a rundown of the procedure:

The first step in the process of making a roll-up standee is to design the graphics or images that will be printed on the standee. These designs will be printed on the standee. This can be accomplished with the help of specialised software for graphic design, such as Adobe Illustrator or Photoshop. It is essential to make certain that the layout is of high quality, that it is clear, and that it can be read from a distance.

Printing: The next step is to use a large-format digital printing machine to print the design onto a piece of vinyl. The printing process guarantees that the image will be of vibrant colour, of high quality, and that it will last for a long time. Because of its longevity, flexibility, and resistance to fading, vinyl was selected as the material of choice.

After the design has been printed on the vinyl material, the next step is to cut the material to the desired dimensions using the cutting tool. This can be accomplished with the help of a vinyl cutter or another type of cutting machine. The roll-up mechanism that will be used for the standee typically requires the vinyl material to be cut to the appropriate dimensions before it can be used.

After the mounting process is done, the vinyl material is then put on the roll-up mechanism. To finish this step, you must attach the top of the vinyl material to the top of the mechanism, which is usually a pole that can be pulled out and used to hold the standee in place.

Standee assembly can begin once the vinyl material has been firmly attached to the roll-up mechanism and the standee is ready to be put together. The next step is to add any extra parts, like a stand or base, to the main picture. After that, the standee is disassembled and packed away into a carrying case for convenience.

The main steps in making a roll-up standee printing are designing the graphics, printing them on vinyl, cutting the vinyl to size, attaching it to a roll-up mechanism, and putting the standee together. If you have the right tools and know-how, you can finish the job quickly and well. This will give businesses a high-quality marketing tool that can be taken anywhere.